Common Weather Resistance Testing Methods

Common Weather Resistance Testing Methods

Weather resistance testing ensures exterior materials can withstand harsh conditions like UV rays, moisture, and temperature changes. This is critical for durability, saving money on repairs, and maintaining structural integrity over time.

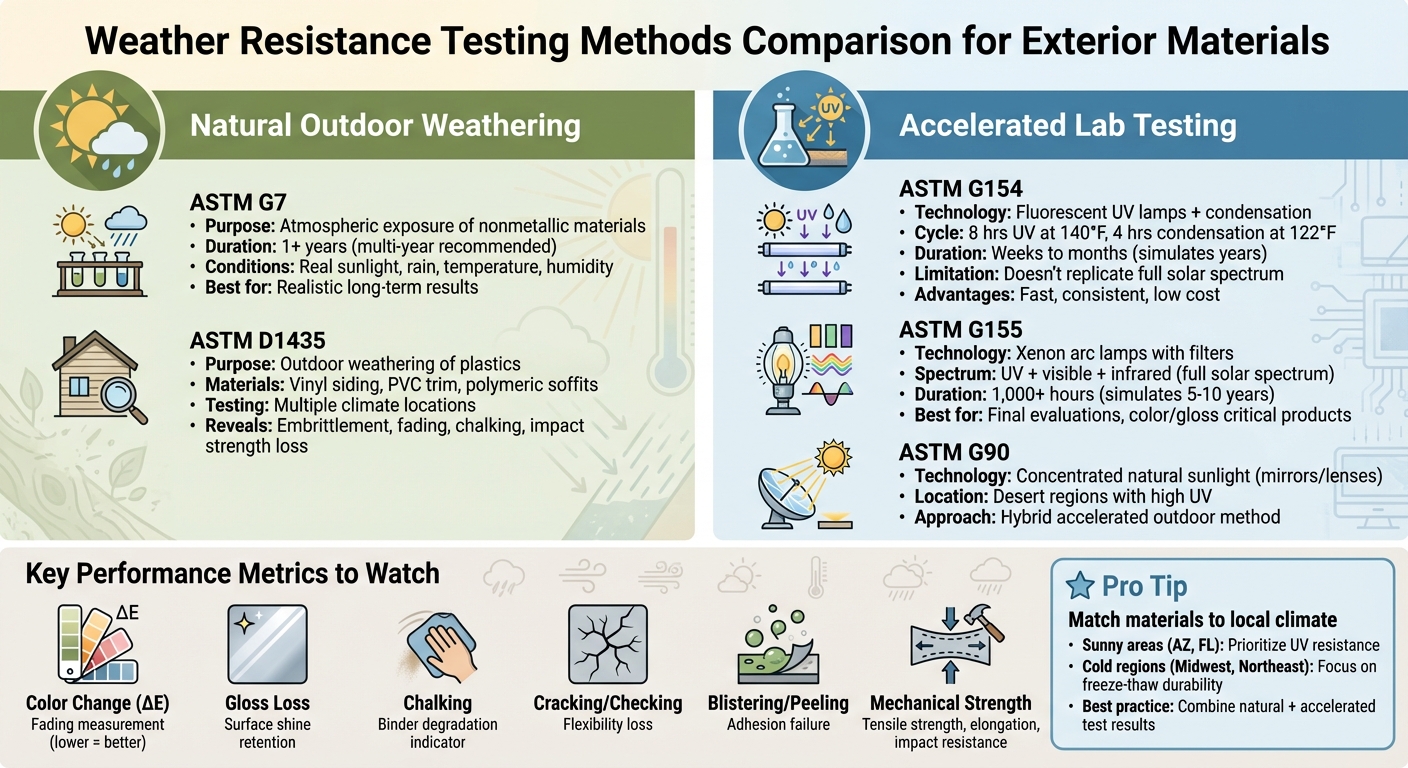

Key methods include:

- Natural Weathering: Real-world exposure to sunlight, rain, and temperature changes (e.g., ASTM G7, D1435). Provides realistic but slower results.

- Accelerated Testing: Simulates years of wear in weeks using UV light, moisture, and heat (e.g., ASTM G154, G155). Faster but less precise for lifespan predictions.

Metrics to watch: Color fading (ΔE), gloss loss, cracking, and mechanical strength retention. Combine natural and lab results for the best material choices.

For example, ASTM G154 uses UV lamps and condensation cycles, while ASTM G155 replicates the full solar spectrum with xenon arc lamps. Both assess durability but serve different needs.

Pro tip: Match materials to your local climate. For sunny areas, prioritize UV resistance. For colder regions, focus on freeze-thaw durability. Reliable test data helps homeowners and contractors make informed decisions.

Weather Resistance Testing Methods Comparison: Natural vs Accelerated

Atlas Online Seminar – Part 4: Weathering Testing and Basic Standards

Natural Outdoor Weathering Methods

Natural outdoor weathering exposes test materials to real-world conditions like sunlight, rain, temperature changes, humidity, and pollutants. These tests can last anywhere from one to several years, offering insight into how materials age under actual environmental influences. Unlike accelerated lab tests, natural weathering reflects the true effects of a specific climate, making it an essential complement to laboratory evaluations. Together, these methods help create a complete picture of a material's durability.

ASTM G7: Atmospheric Exposure of Nonmetallic Materials

The ASTM G7 standard focuses on evaluating how nonmetallic materials weather in natural outdoor conditions. This involves placing materials on test racks positioned to capture maximum solar radiation, with exposure durations based on cumulative UV exposure. The standard recommends testing for at least one year, with multi-year studies at multiple locations offering even more valuable data. Detailed documentation is critical, including the test site's location, the orientation and tilt of the racks, mounting methods, and exposure start and end dates. Optional data on temperature, humidity, and rainfall can provide additional context for comparing results across different regions, helping researchers understand how materials perform in varying environments.

ASTM D1435: Outdoor Weathering of Plastics

ASTM D1435 offers guidelines for assessing the long-term outdoor performance of plastic materials, such as vinyl siding, PVC trim boards, and polymeric soffits. These materials face challenges like embrittlement, fading, chalking, and reduced impact strength due to prolonged exposure to UV radiation, temperature shifts, and moisture. Testing across multiple locations with distinct climates - humid versus arid, for example - reveals how plastics respond to different environmental conditions. By comparing these results, manufacturers can pinpoint vulnerabilities in their formulations and make necessary adjustments, such as improving stabilizers, pigments, or material thickness. This ensures that plastic components maintain consistent performance, regardless of where they're installed across the United States.

Accelerated Laboratory Weathering Methods

Accelerated weathering tests build upon natural outdoor testing but are designed to deliver quicker insights into material durability. While natural testing provides realistic results, it often takes years to complete. Accelerated methods, on the other hand, compress years of environmental exposure into mere weeks or months by using light, heat, and moisture cycles to speed up material degradation. This allows manufacturers to compare the durability of different materials much faster. These methods are particularly useful for making relative comparisons between coatings or siding systems. However, the results don’t directly translate into precise service life predictions because the acceleration factor can vary depending on the material’s formulation.

ASTM G154: Fluorescent UV and Condensation Testing

ASTM G154 uses fluorescent UV lamps and moisture cycles to simulate the effects of sunlight, dew, and rain in a controlled environment. During this test, materials like paints, coatings, plastics, sealants, siding finishes, and roofing membranes are placed in a chamber and subjected to alternating cycles of UV radiation and condensation. A typical cycle involves 8 hours of UV exposure at approximately 140°F, followed by 4 hours of condensation at around 122°F. These cycles are repeated for hundreds or even thousands of hours.

This testing method can highlight critical issues such as color fading, chalking, gloss loss, cracking, blistering, and adhesion failure - all of which can affect the performance and appearance of exterior materials. The advantages of ASTM G154 include shorter test durations, consistent results across labs, and relatively low costs. However, it has a limitation: fluorescent UV lamps don’t fully replicate the complete solar spectrum, particularly the visible and infrared wavelengths. As a result, some heat- and color-related deterioration may go undetected.

ASTM G155: Xenon Arc Exposure Testing

ASTM G155 takes a different approach by using xenon arc lamps with filters to closely replicate the entire solar spectrum, including UV, visible, and infrared radiation. This method exposes materials like prefinished siding, coatings, or composite trims to cycles that combine xenon light with controlled temperature, humidity, and water spray. These conditions simulate the combined effects of sunlight, heat, and moisture.

Because of its ability to mimic natural daylight more accurately, ASTM G155 provides a more realistic assessment of how materials will hold up under long-term sun exposure. Manufacturers often use ASTM G154 early in product development to screen potential formulations and then turn to ASTM G155 for final evaluations, especially when visual qualities like color and gloss are critical. Tests typically last over 1,000 hours, simulating between 5 and 10 years of outdoor exposure, depending on the material. This makes it an essential tool for selecting products with proven resistance to UV and moisture.

ASTM G90: Accelerated Outdoor Weathering with Concentrated Sunlight

ASTM G90 takes a hybrid approach by using concentrated natural sunlight for accelerated outdoor weathering. Unlike methods that rely on artificial light, this test uses mirrors or lenses to focus real sunlight onto test specimens. It’s often conducted in areas with high UV exposure, such as desert regions.

sbb-itb-85e0110

How to Use Test Results for Material Selection

Key Performance Metrics

When reviewing weathering test reports, focus on the measurements that directly address practical concerns. For example, color change (ΔE) indicates how much fading you can expect - a lower number means the material will retain its original look longer, while higher numbers suggest noticeable fading over time. Gloss loss measures how quickly a surface might lose its shine, which is especially critical for darker finishes that can appear dull and worn more quickly. Additionally, chalking and surface erosion highlight binder degradation, which can lead to more frequent repainting and make the surface more prone to dirt buildup.

You’ll also want to look for signs of cracking, checking, blistering, and peeling. These are red flags for loss of flexibility and adhesion, which can allow water to seep behind siding, potentially causing rot or structural issues. Lastly, consider retention of mechanical properties like tensile strength, elongation, and impact resistance after exposure. Materials that maintain their strength are better equipped to handle wind, thermal expansion, and physical impacts over time.

Natural vs. Accelerated Testing Methods

Understanding these metrics can guide your choice between natural and accelerated testing methods. Natural outdoor weathering, such as testing under ASTM G7, exposes materials to real-world conditions like sunlight, rain, humidity, and temperature fluctuations, often over 24 months or more. This type of testing provides a realistic view of how a product will age in actual use. However, results can vary depending on the test location - data from a subtropical site in Florida may not reflect how the material will perform in colder, freeze-thaw climates.

Accelerated tests, such as ASTM G154 and G155, simulate years of exposure in a fraction of the time. Using controlled UV lamps, moisture cycles, and heat, these tests deliver faster results and allow for consistent comparisons across different labs. They’re especially useful for screening materials during product development.

That said, accelerated testing primarily provides relative rankings rather than precise service life predictions. To make the best decisions, compare products side-by-side under identical conditions and prioritize materials that also perform well in natural exposure tests conducted in environments similar to your project’s location.

What This Means for Homeowners and Contractors

Weathering test data plays a crucial role in choosing materials. Products that show minimal fading, gloss loss, or cracking often come with extended warranties, which can reduce maintenance needs over the years.

Match test results to your local conditions. For sunny areas like Arizona or Florida, focus on materials with strong UV and fade resistance. In regions like the Midwest or Northeast, prioritize moisture resistance and durability against freeze-thaw cycles.

Experienced contractors, such as Bayshore Exteriors, which specializes in James Hardie siding and full exterior remodeling, can help interpret manufacturer test data. They’ll guide you in selecting materials that have proven performance in your region and ensure proper installation techniques to maintain the tested durability. This expert insight allows you to base your decisions on evidence rather than marketing claims, whether you’re planning a siding update, new construction, or a complete exterior renovation.

Conclusion

Weather resistance testing is all about comparing how materials perform under specific conditions - not about predicting their exact lifespan. Standards like ASTM G7, G154, and G155 provide reliable ways to rank materials, but they don’t offer absolute durability predictions since acceleration factors differ based on material type and formulation. To get the most accurate insights, combine natural outdoor exposure data with accelerated lab results, especially from regions that closely match your project’s climate.

Geographic location plays a huge role in how materials hold up over time. Factors like UV exposure, humidity, freeze-thaw cycles, and wind-driven rain can vary significantly across the United States. That’s why ASTM advocates for multi-site exposure testing. Contractors who understand these local climate variations are better equipped to recommend materials that perform well in specific environments.

For expert advice, consult professionals like Bayshore Exteriors. Their knowledge of ASTM weathering standards and experience with Florida’s subtropical climate ensure that materials like James Hardie siding are installed to maximize tested durability. This kind of expertise bridges the gap between technical data and practical application.

FAQs

What’s the difference between natural and accelerated weather resistance testing, and how do I choose the right one for my project?

Natural weather resistance testing involves exposing materials to outdoor conditions over an extended period to evaluate how well they hold up. While this method delivers precise insights for specific climates, it requires significant time - sometimes months or even years - to yield results. On the other hand, accelerated weather resistance testing recreates environmental factors like UV exposure, rainfall, and temperature shifts in a lab-controlled environment. This method is much quicker, providing results in just days or weeks, making it a go-to option for time-sensitive projects.

When choosing between these methods, think about your project’s timeline, budget, and the accuracy needed for your environment. If you're unsure which route to take, consulting experts such as Bayshore Exteriors can guide you toward the right decision to ensure your materials are prepared to endure the elements.

What should I consider when choosing exterior materials for different weather conditions?

When choosing materials for the exterior of your home, it’s crucial to think about how they’ll hold up against the weather in your area. For instance, if you live in a place with lots of rain or high humidity, you’ll want to go with moisture-resistant options like fiber cement siding to prevent rot. On the other hand, if you’re in a region with intense heat or freezing temperatures, prioritize materials that offer solid thermal stability and insulation.

It’s also a good idea to check that the materials meet ASTM weather resistance standards. These standards assess how well materials endure environmental challenges like UV rays, strong winds, and temperature swings. Picking the right materials doesn’t just make your home more durable - it also helps keep it looking great and preserves its value for years to come.

Why is it important to use both natural and accelerated weather resistance testing methods?

Combining natural and accelerated weather resistance testing gives a fuller picture of how durable a material truly is. Natural testing subjects materials to real-world conditions, revealing how they hold up in specific climates or environments over time. In contrast, accelerated testing speeds things up, replicating years of wear and tear in a controlled setting within a fraction of the time.

Using both methods together allows you to spot potential flaws more quickly while also verifying how well the material performs in real-life situations. This dual strategy helps ensure that exterior building materials can stand the test of time and meet durability expectations.