Top Materials for Preventing Thermal Bridging

Top Materials for Preventing Thermal Bridging

Thermal bridging can cause up to 30% of heat loss in homes, leading to higher energy bills and discomfort. In hot, humid climates like Florida, it also increases cooling costs and risks condensation, which can result in mold. Addressing thermal bridging is critical for energy efficiency and maintaining a comfortable indoor environment.

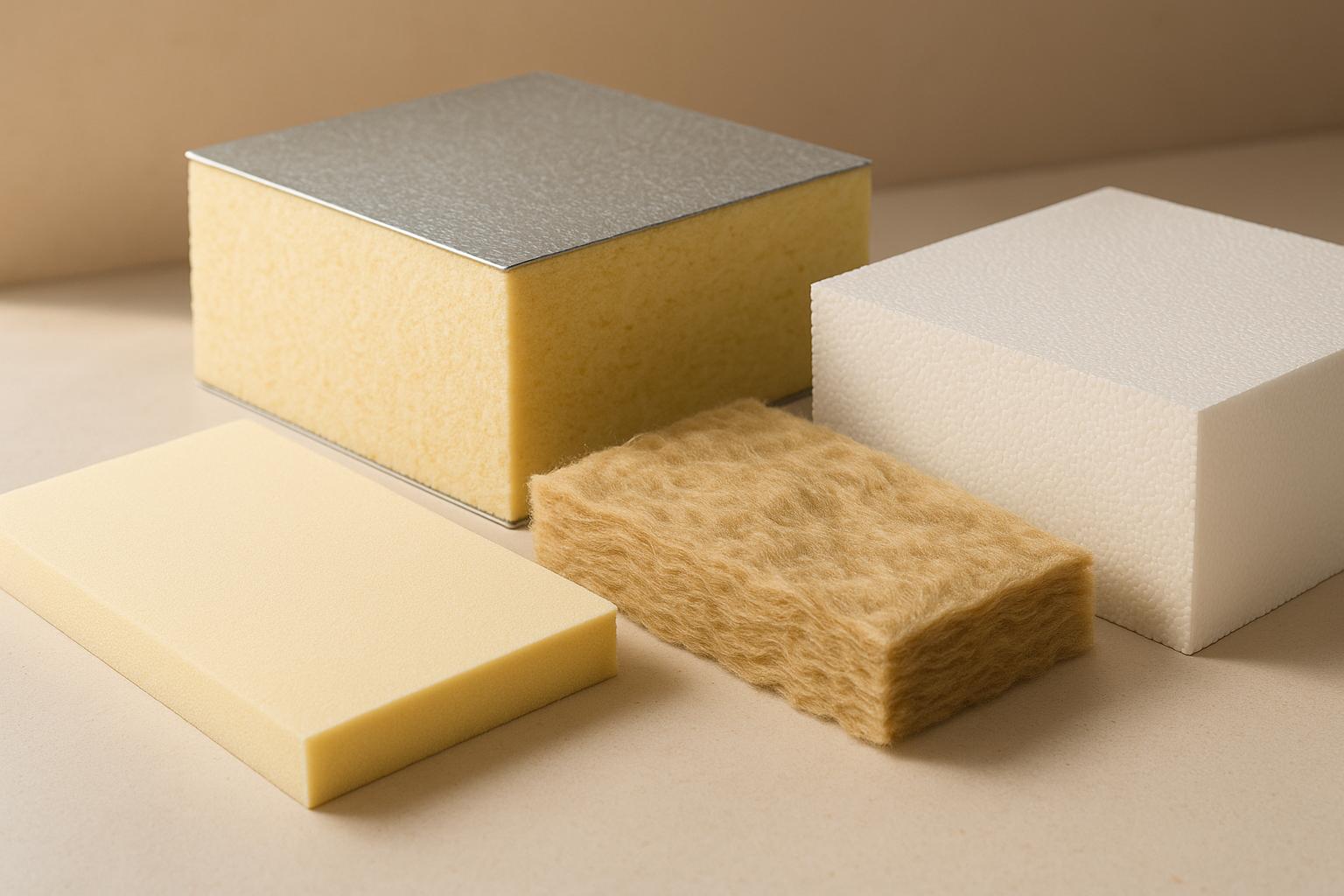

Here are the top materials to reduce thermal bridging:

- Rigid Foam Insulation Boards: High R-value (up to R-6.8 per inch), moisture-resistant, and durable. Ideal for continuous insulation but costs more upfront.

- Mineral Wool Boards: R-value ~4 per inch, excellent moisture resistance, and soundproofing. Affordable and eco-friendly.

- Insulated Concrete Forms (ICFs): Complete wall systems with R-values up to R-24. Durable, mold-resistant, and energy-efficient.

- Structural Insulated Panels (SIPs): High R-value, airtight, and quick to install. Great for whole-wall systems but pricier.

- Loose-Fill/Blown-In Insulation: Affordable and effective for retrofits, with R-values up to 3.8 per inch. Works well in attics and wall cavities.

- Aerogel Panels: Ultra-thin with an R-value of 10.3 per inch. Best for tight spaces but expensive.

Quick Comparison

| Material | R-Value per Inch | Moisture Resistance | Cost Range ($/sq ft) | Best Use |

|---|---|---|---|---|

| Rigid Foam Boards | 3.8–6.8 | Excellent | $0.50–$2.00 | Continuous insulation |

| Mineral Wool Boards | ~4 | Good | $1.00–$3.00 | Walls, soundproofing |

| Insulated Concrete Forms | ~4 | Excellent | $4.00–$8.00 | New construction |

| Structural Insulated Panels | ~4 | Good | $7.00–$12.00 | Whole-wall systems |

| Loose-Fill Insulation | 3.2–3.8 | Fair to Good | $0.75–$2.50 | Retrofitting, attics |

| Aerogel Panels | 10.3 | Excellent | $3.00–$15.00 | Space-constrained retrofits |

Choosing the right material depends on your budget, climate, and specific insulation needs. Each option offers distinct benefits for reducing thermal bridging and improving energy efficiency.

Thermal Bridging!!! Comparing ICF and Alternatives

1. Rigid Foam Insulation Boards

Rigid foam insulation boards are an excellent choice for creating a continuous thermal barrier that significantly reduces heat transfer. These boards cover entire surfaces, ensuring consistent insulation across walls, roofs, or other areas.

R-value per Inch

The effectiveness of rigid foam boards is measured by their R-value per inch, which varies by material type. Here’s a quick breakdown:

| Rigid Insulation Type | R-value per inch |

|---|---|

| Polyisocyanurate (Polyiso) | R-6.5 to R-6.8 |

| Extruded Polystyrene (XPS) | R-5 |

| Graphite Polystyrene (GPS) | R-4.7 |

| Expanded Polystyrene (EPS) | R-3.8 |

Polyiso offers the highest R-value, making it a top choice for areas requiring maximum insulation in minimal space.

Moisture and Climate Suitability

In Florida’s humid environment, moisture resistance is a major factor. Rigid foam boards are designed to resist water absorption, making them highly effective in maintaining insulation performance over time. For example, EPS rigid foam absorbs an average of just 0.2% moisture by weight and retains 95% to 97% of its thermal efficiency, even in damp conditions. This feature helps prevent mold growth, a common issue with materials like fiberglass that lose effectiveness when wet.

Additionally, rigid foam boards provide continuous insulation, which helps maintain steady indoor temperatures. This reduces the strain on air conditioning systems, a critical benefit in Florida, where cooling systems run nearly all year. The closed-cell structure of these boards not only enhances thermal performance but also prevents moisture from seeping in, ensuring long-lasting durability.

Cost-Effectiveness

While rigid foam boards come with a higher upfront cost compared to fiberglass, they deliver excellent long-term value. For instance, insulating a 10-square-foot wall to R-15 costs about $10 with rigid foam, compared to $3.40 to $4.00 with fiberglass. However, the energy savings can be substantial - rigid foam insulation can reduce energy bills by up to 40%. It’s also more affordable than spray foam, costing less than half the price.

Over time, the energy savings often offset the initial investment, making rigid foam a smart choice for homeowners looking to improve both comfort and efficiency.

At Bayshore Exteriors, we specialize in properly installing rigid foam insulation to ensure maximum performance and long-term benefits for your home.

2. Mineral Wool Boards

After covering rigid foam insulation, let's dive into another solid option: mineral wool boards. These boards offer effective insulation and help address thermal bridging without breaking the bank. Made from molten basalt or slag, they provide consistent insulation while tackling key concerns for homeowners in Florida.

R-value per Inch

Mineral wool boards typically have an R-value of about 4 per inch, which can increase to approximately 5 per inch when applied as continuous insulation. This means they outperform standard fiberglass batts by about 22–37% in R-value per inch. While polyiso insulation reaches R-6 per inch, mineral wool’s R-4 rating strikes a balance between effective thermal performance and affordability.

Moisture and Mold Resistance

Florida’s humid environment makes moisture resistance a must, and mineral wool boards deliver on this front. Thanks to their inorganic makeup, they don’t break down in high humidity (up to 90%) or even during flooding. This durability ensures they retain their R-value even when exposed to moisture. On top of that, their hydrophobic properties promote water drainage and drying within wall cavities, making them a practical choice for Florida homes. Their ability to manage moisture pairs perfectly with the vapor permeability needed in this climate.

Suitability for Florida Climate

Mineral wool boards are an excellent fit for Florida’s weather. They allow vapor to pass through, making them ideal for exterior insulation without the risk of trapping moisture. This breathability helps prevent moisture buildup, which could otherwise lead to long-term structural problems. Additionally, mineral wool excels at soundproofing, blocking up to 95% of airborne noise (STC 45). This makes it a great choice for homes near busy streets or in crowded neighborhoods.

Cost-Effectiveness

Although mineral wool boards are more expensive than fiberglass, they retain 90% of their insulating value throughout their lifespan and can cut heating and cooling costs by 40–60%. They’re also a greener option, containing 70% recycled materials compared to fiberglass’s 20–30%. Products like ROCKWOOL Comfortboard are specifically engineered to help reduce thermal bridging. Combining performance, durability, and long-term savings, mineral wool boards are a smart addition to any continuous insulation plan.

At Bayshore Exteriors, we know how to make the most of mineral wool boards to enhance your home’s energy efficiency while standing up to Florida’s demanding climate.

3. Insulated Concrete Forms (ICFs)

Insulated Concrete Forms (ICFs) are a complete wall system designed to eliminate thermal bridging by sandwiching a concrete core between two layers of continuous insulation. This design ensures consistent insulation performance, which is especially important in Florida’s climate. ICFs are made up of interlocking foam blocks that form a concrete wall, offering excellent thermal performance for homes in the state.

R-value per Inch

Concrete on its own has a very low R-value - about R-0.08 per inch. However, when integrated into an ICF system, the thermal performance improves significantly. For instance, Fox Blocks ICF achieves an R-value of R-22. Building codes evaluate the overall thermal efficiency of the wall assembly, with a simple Fox Blocks wall reaching an R-value of R-24. For even better performance, adding a Fox Blocks Energy Stick can push the R-value above R-30. Testing by Oak Ridge National Laboratory (ORNL) shows that the "clear wall" R-value for ICF walls is around 12. This combination of high thermal performance and moisture resistance makes ICFs an excellent choice for Florida homes.

Moisture and Mold Resistance

Florida’s humid climate demands construction materials that can resist moisture, and ICFs excel in this area. The concrete core provides outstanding moisture resistance, while the continuous insulation layers help prevent condensation - an issue common in traditional framed walls. ICFs are also resistant to mold and pest infestations, making them a solid choice for humid environments.

Suitability for Florida Climate

ICFs are particularly well-suited for Florida’s unique climate. Their superior insulation helps reduce energy consumption and maintain steady indoor temperatures, even during the state’s hot summers. Homes built with ICF walls use 32% less energy for cooling and 44% less energy for heating compared to wood-framed homes. Additionally, ICF walls are built to withstand Florida’s extreme weather, including winds over 200 MPH and debris impacts at speeds exceeding 100 MPH. With Florida’s average morning humidity at 86.4% and summer highs often above 90°F, ICFs provide the thermal mass and insulation needed to keep homes comfortable while cutting energy costs.

Cost-Effectiveness

While ICF construction adds 3-5% to initial building costs, the long-term savings make it a smart investment. Homes built with ICFs can save up to 50% on energy bills due to superior airtightness and lower utility costs. For example, monthly utility expenses average just $0.03 per square foot for ICF homes, compared to $0.10 per square foot for wood-frame homes. ICF structures also experience significantly less air leakage, with only 1.26 Air Changes per Hour (ACH) compared to 4.8 ACH in light wood-frame homes. Over 30 years, these energy savings often result in ICF homes costing less overall, despite the higher upfront investment.

At Bayshore Exteriors, we recognize how ICF construction can dramatically improve your home’s energy efficiency while offering unparalleled protection against Florida’s challenging weather conditions.

4. Structural Insulated Panels (SIPs)

Structural Insulated Panels (SIPs) are an all-in-one building solution that combines strength and insulation in a single panel. Each panel features an insulating foam core sandwiched between two structural facings, usually made of oriented strand board (OSB). This design eliminates heat loss effectively by integrating both structure and insulation. Let’s dive into how SIPs perform in terms of thermal efficiency, moisture resistance, and suitability for specific climates like Florida.

R-Value per Inch

SIPs maintain their rated R-value consistently, avoiding the thermal bridging losses common in traditional stud-framed walls. This means SIP homes deliver the insulation performance they promise.

Here’s a breakdown of R-values based on panel type and thickness:

| Panel Thickness | White EPS R-Value | Grey GPS R-Value |

|---|---|---|

| 4 1/2" | 15.4 | 18.3 |

| 6 1/2" | 23.2 | 27.7 |

| 8 1/4" | 30.0 | 35.9 |

| 10 1/4" | 37.8 | 45.3 |

| 12 1/4" | 45.6 | 54.7 |

Premier SIPS MAX panels, made with GPS cores, deliver up to 41% higher warranted R-values compared to traditional stick-framed walls with batt insulation. For reference, a 5 1/2-inch polyurethane SIP panel from RAYCORE achieves an R-value of 42, while a 6 1/2-inch EPS sandwich panel reaches R-24.

Moisture and Mold Resistance

SIPs are designed to resist moisture, swelling, and mold when properly sealed. Using foam or tape to seal seams and penetrations ensures airtight performance, with air leakage rates below 3 ACH at 50 Pascals. In humid climates like Florida, this is especially important. Some manufacturers enhance SIPs further with borate-treated foam and OSB to deter termites and improve moisture resistance.

Given Florida’s heavy rainfall - often exceeding 20 inches annually - installing claddings with a drainage gap between the cladding and the weather-resistant barrier is recommended. This added layer of protection ensures durability in challenging environments. Beyond moisture control, SIPs also demonstrate strong resilience against regional weather conditions.

Suitability for Florida Climate

SIPs are well-suited to Florida’s hot, humid climate and extreme weather conditions. They can withstand wind speeds over 180 mph and have proven durability even after flooding [54, 65, 59]. Their continuous insulation helps maintain stable indoor temperatures, which is critical in Florida’s high-heat environment.

In addition to comfort, SIPs offer significant energy savings. They can cut annual heating and cooling costs by 40–60%. A 6.5-inch SIP wall meets or exceeds residential energy codes in every U.S. climate zone. Compared to traditional timber framing, SIPs are approximately 50% more energy-efficient, with whole-wall energy efficiency 51% higher than standard two-by-six, R-19 construction. Even a thinner 2x4 SIP wall can outperform a conventional 2x6 wall.

Cost-Effectiveness

While SIPs may come with higher upfront material costs, the long-term savings are hard to ignore. Their airtight construction can make SIP homes up to 15 times more airtight than wood-framed homes with fiberglass insulation. This translates to lower utility bills and more efficient HVAC operation, especially in high-cooling-demand areas like Florida.

SIPs also save time on the construction site. A BASF study found that using SIPs reduces jobsite labor needs by 55%. Additionally, building with SIPs allows for a building envelope to be completed up to 55% faster than traditional methods. These time savings, combined with energy efficiency, make SIPs a smart choice for durable, cost-effective construction in Florida’s challenging climate.

sbb-itb-85e0110

5. Loose-Fill and Blown-In Insulation

Loose-fill and blown-in insulation are excellent for filling gaps left by standard batts, helping to minimize thermal bridging. These types of insulation are installed using pneumatic equipment, making them particularly useful for retrofits. They also help reduce air leaks and moisture infiltration, which are key concerns in many climates. Let’s take a closer look at their thermal performance and suitability.

R-Value per Inch

The thermal efficiency of blown-in insulation varies based on the material used:

- Cellulose: Offers an R-value between 3.2 and 3.8 per inch.

- Fiberglass: Typically ranges from 2.2 to 4.3 per inch, with an average of about 3.2 to 3.7.

- Mineral Wool: Falls within 2.2 to 3.3 per inch.

For example, Greenfiber's SANCTUARY® insulation delivers an R-value of 3.7 per inch, outperforming standard fiberglass and mineral wool options. Additionally, dense-packed cellulose tends to achieve roughly 1 R-value unit higher than its loose-blown counterpart, though precise installation is key to achieving these results.

Moisture and Mold Resistance

Managing moisture is especially important in humid environments like Florida. Treated cellulose insulation performs well in these conditions. According to a 2022 University of Florida study, borate-treated cellulose can reduce mold growth by 85% in humid areas. Fiberglass, while cost-effective, may retain moisture if not paired with proper air sealing and vapor barriers. Mineral wool stands out for its ability to maintain its R-value even when exposed to moisture, along with its mold-resistant and non-combustible properties, making it ideal for coastal or fire-prone homes.

| Insulation Type | R-Value (per inch) | Key Benefits | Best Use in Florida |

|---|---|---|---|

| Fiberglass | R-2.2–R-2.7 | Affordable, non-flammable | Low- to moderate-humidity areas with vapor barriers |

| Cellulose | R-3.2–R-3.8 | Eco-friendly, pest/mold-resistant (when borate-treated) | High-humidity climates, retrofits |

| Mineral Wool | R-3.0–R-3.3 | Mold/moisture-proof, non-combustible | Coastal homes, fire-prone areas |

Suitability for Florida Climate

Loose-fill insulation is well-suited for Florida's intense heat and humidity. It conforms tightly to cracks and crevices, effectively blocking humid air from entering attics and walls. This reduces thermal bridging, a major source of energy loss, and moisture infiltration. According to ENERGY STAR, pairing cellulose insulation with proper air sealing can lead to approximately 20% energy savings in humid climates. Additionally, loose-fill insulation has been shown to reduce heat gain by up to 30% and cut air infiltration by about 30% compared to batt insulation.

Cost-Effectiveness

Loose-fill insulation is an affordable option for many homeowners:

- Fiberglass: The most budget-friendly, with DIY costs ranging from $0.90–$1.80 per square foot and professional installation priced at $1.47–$2.93 per square foot [31,68].

- Cellulose: Slightly more expensive, costing $1.20–$1.90 per square foot for DIY projects, and $1.98–$4.40 per square foot for professional installation.

- Mineral Wool: The premium choice, with material costs between $2.50–$4.00 per square foot and professional installation ranging from $2.93–$5.85 per square foot.

Proper installation of fiberglass insulation in airtight homes can lower HVAC costs by 10–15%, according to ENERGY STAR. Bayshore Exteriors ensures optimal energy efficiency by combining high-quality insulation with exterior upgrades.

6. Aerogel Panels

When it comes to insulation, traditional materials like rigid foam and mineral wool have long been reliable choices. However, aerogel panels offer a cutting-edge alternative, especially for tackling specific thermal bridging issues. Made from silica and composed of over 90% air, aerogel is an incredibly lightweight yet high-performing material that minimizes thermal bridging effectively.

R-Value per Inch

Aerogel stands out for its exceptional thermal performance, boasting an R-value of 10.3 per inch. To put this into perspective, it provides more than twice the insulation of rigid fiberglass, which has an R-value of 4 per inch. Its low thermal conductivity, ranging from 0.013 to 0.015 W/(m·K), further underscores its efficiency compared to mineral wool, which has a thermal conductivity of 0.03–0.04 W/(m·K). When compared to other common materials like fiberglass (R-value ≈4 per inch) and polyiso foam (R-value 5.6–8 per inch), aerogel's R-value and a K-Factor as low as 0.01 deliver superior insulation in much thinner layers. This makes aerogel particularly appealing for renovations in Florida, where space constraints often demand thinner insulation profiles.

Suitability for Florida Climate

Aerogel’s high thermal resistance in thin layers - less than 2 cm - makes it an excellent choice for retrofitting older Florida homes. Its slim profile allows it to improve insulation without compromising architectural details, a key consideration in maintaining the character of older properties.

Cost-Effectiveness

Aerogel is undeniably a premium product, with material costs ranging from $2 to $10 per square foot and installed costs between $3 and $15 per square foot. For example, 5mm aerogel panels are priced at $3.79 per square foot, while 10mm panels cost $5.72 per square foot. Insulating a 2,000-square-foot home could require an investment of $6,000 to $30,000. Some estimates suggest costs of around $2 per square foot for just an inch of material, while commercial-grade aerogel is often priced at $4 per square foot.

"More than you want to pay... Aerogel is quite thin, which makes it appropriate for odd conditions where you have to keep a very narrow profile and still meet some energy code requirements. Even in very high-end residences, where presumably money is not an issue, no one is going to use Aerogel as the primary building insulation. There are simply products that will work well enough for what you need at a much more reasonable cost."

– Anne Whitacre, Architectural specifier for large projects at Multiple Large Firms

While the upfront cost of aerogel is high, its exceptional insulating properties can lead to notable energy savings over time, potentially offsetting the initial expense. However, it’s best suited for targeted applications, such as addressing specific thermal bridging problems, rather than being used as a whole-house insulation solution. To ensure optimal performance, aerogel requires careful handling during installation. Professional contractors like Bayshore Exteriors can ensure the material is applied correctly, preserving its unique insulating capabilities.

Material Comparison Table

Below is a table that compares six insulation options based on their R-value, moisture resistance, cost, and ideal uses for Florida homes.

| Material | R-Value per Inch | Moisture Performance | Cost Range ($/sq ft) | Best Application for Florida Homes |

|---|---|---|---|---|

| Rigid Foam Insulation | 5.0 (XPS) | Excellent | $0.50 - $2.00 | Continuous exterior insulation, foundation walls |

| Mineral Wool Boards | 3.5 - 4.0 | Good (vapor permeable) | $1.00 - $3.00 | Fire-resistant uses, sound control |

| Insulated Concrete Forms (ICFs) | 3.9 - 4.4 (EPS core) | Excellent | $4.00 - $8.00 | New construction, hurricane-resistant builds |

| Structural Insulated Panels (SIPs) | 3.9 - 4.4 | Good with proper sealing | $7.00 - $12.00 | Whole-wall systems, fast construction |

| Loose-Fill/Blown-In Insulation | 3.5 - 3.6 | Fair to Good | $0.75 - $2.50 | Retrofitting existing walls, attic spaces |

| Aerogel Panels | 10.3 | Excellent | $3.00 - $15.00 | Space-constrained retrofits, premium applications |

For instance, fiberglass batts, which typically have an R-value of around 3.5 per inch, may underperform in real-world conditions. A 2×6 wall using R-19 fiberglass insulation might only achieve about R-13.7 due to thermal bridging. This highlights why materials like SIPs often retain their full R-value in whole-wall tests, as they minimize heat loss from thermal bridging and air infiltration.

Mineral wool offers another advantage: its vapor permeability helps manage condensation within wall assemblies. Cost ranges in the table include material and installation expenses. For example, aerogel panels are a premium option, while loose-fill insulation is more budget-friendly.

Proper installation is key to achieving the expected performance, especially for materials like rigid foam that rely on continuous exterior application.

This table provides a starting point, but the best choice depends on your specific project needs, budget, and goals. Matching each material's strengths to your home's requirements is essential for long-term performance and comfort.

Conclusion

Choosing the right insulation materials can significantly enhance energy efficiency and comfort in your Florida home. With sidewalls accounting for nearly 35% of a home's energy loss, investing in effective insulation isn't just smart - it’s essential for your property’s performance over time.

Florida’s subtropical climate, marked by high temperatures and humidity, calls for insulation solutions that address these unique challenges. The materials highlighted in this article - like rigid foam insulation for continuous coverage, insulated concrete forms (ICFs) for better energy performance, or aerogel panels for tight spaces - each bring specific benefits to the table. The goal is to align the material’s properties with your project’s needs, especially when tackling thermal bridging issues.

Proper material selection and installation play a critical role in maintaining a comfortable and healthy indoor environment, particularly in Florida’s humid conditions. The U.S. Department of Energy underscores the importance of addressing insulation during exterior renovations, noting that proper installation - free from gaps or compression - is key to achieving optimal results.

For homeowners looking to upgrade their exterior and combat thermal bridging, Bayshore Exteriors offers 15 years of expertise in exterior remodeling. From James Hardie siding to advanced insulation solutions, their skilled team delivers quality workmanship tailored to Florida’s climate.

FAQs

What should I look for when selecting insulation for a humid climate like Florida?

When selecting insulation for Florida's humid climate, it's essential to prioritize materials that resist moisture, discourage mold growth, and deliver a high R-value for better energy efficiency. Two popular choices are spray foam, which effectively seals air leaks and keeps moisture at bay, and radiant barriers, designed to reflect heat and maintain cooler indoor temperatures.

Getting the installation right is just as important - poorly installed insulation can trap moisture, causing long-term issues. Bayshore Exteriors specializes in helping homeowners choose and properly install insulation to boost comfort and durability, tailored to Florida's challenging climate.

Are high-performance insulation materials worth the upfront cost in terms of long-term energy savings?

Investing in high-performance insulation might seem pricey at first, but it can lead to noticeable savings on energy bills over time. In fact, homeowners typically see heating and cooling costs drop by 15% or more, often recouping the initial expense within just a few years.

For Florida homes, where keeping indoor temperatures comfortable is a constant need, these insulation materials are particularly useful. The reduced energy use and increased comfort they provide make them a practical and economical way to boost energy efficiency.

What are the advantages of using aerogel panels for insulation, and are they worth the higher cost?

Aerogel panels are a standout choice for insulation thanks to their incredibly porous structure, which delivers excellent thermal resistance while staying thin and lightweight. This combination makes them perfect for cutting energy costs and enhancing indoor comfort, especially in areas where space is limited or top-tier performance is essential.

That said, aerogel panels come with a steep price tag - typically around $15–$17 per square foot. However, their efficiency and ability to save space can make them a smart investment for specialized uses. For homeowners prioritizing energy savings and peak performance, aerogel could be a compelling option despite the higher initial expense.